Co2 Recovery for dry ice production

RE-CO₂ Recovery Systems

Cut Your Liquid CO₂ Costs in Half

Dry ice production relies on liquid CO₂ (LCO₂), but only around half of it converts into usable CO₂ snow during pelletizing. The other half becomes gas that is usually released into the atmosphere—resulting in significant loss and high production costs.

Our RE-CO₂ Recovery Systems solve this problem by capturing and recycling the exhaust CO₂ gas, feeding it back into the pelletizer to produce more dry ice. This process can reduce your dry ice production cost by up to 40% while dramatically improving LCO₂-to-dry-ice conversion. Built with scalable capacities and a modular design, these systems integrate seamlessly with all Cold Jet dry ice pelletizers and many competitor systems, including integrated blasting units. For facilities looking to increase efficiency, reduce CO₂ waste, and maximize output, the RE-CO₂ Recovery Systems offer the most advanced and sustainable solution.

How It Works

Liquid CO₂ enters the pelletizer

50% becomes CO₂ snow (compressed into dry ice)

50% becomes CO₂ gas

Instead of venting the gas, the RE-CO₂ system captures, liquefies, and returns it to the pelletizer

More dry ice is produced using the same input, significantly lowering operational costs

Choose the Right CO₂ Recovery System

Capacity: Up to 176 lbs/hr (80 kg/hr)

Ideal for pairing with PE 80 dry ice pelletizers.

Perfect for small to mid-size dry ice production setups.

RE-CO₂ 80

Capacity: Up to 352 lbs/hr (160 kg/hr)

Best suited for PR120H pelletizers.

Offers higher recovery efficiency for expanding operations.

RE-CO₂ 160

Capacity: Up to 705 lbs/hr (320 kg/hr)

Designed for PR350H and PR750H pelletizers.

The most intelligent, scalable, and sustainable CO₂ recovery system in its category.

RE-CO₂ 320V2

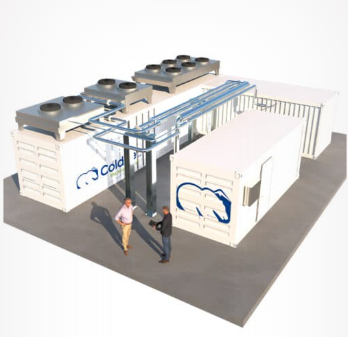

Capacity: Up to 7716 lbs/hr (3500 kg/hr)

A high-capacity, containerized, autonomous CO₂ recovery system.

Best for large-scale production using three or more PR750H pelletizers.

Features the lowest energy consumption per ton recovered and uses CO₂ (R744) as its refrigerant.

RE-CO₂ 3500